The F-35 fighter jet is one of the most hotly debated purchases in recent Canadian history. These U.S.-made planes come with a hefty price tag and are politically charged.

Rising trade tensions with the U.S., along with questions about Canada’s sovereignty, initiated a review of the purchase in the spring. But for the time being, Canada has contractually committed to buying 16 F-35s, with the option to purchase up to 88 of the fifth-generation stealth fighter jets.

“The F-35 is the most capable, it’s the most survivable, and it’s the most lethal [fighter jet],” said Chauncey McIntosh, vice-president and general manager at Lockheed Martin, which runs the F-35 program.

Buying the full complement of F-35s would be the largest investment in the Royal Canadian Air Force in more than 30 years, with a price tag of $27.7 billion — up from $19 billion cited in 2023, after a report from the auditor general.

Canada’s enduring commitment to the F-35 remains contentious, particularly in light of U.S. President Donald Trump’s repeated taunts this year about Canada becoming the 51st state. But the production of one of these jets actually reflects the highly integrated nature of the Canadian and American economies, with parts from both crossing the border before ending up in the final product.

“Canada has been a part of this program from the beginning,” said McIntosh. He’s referring to Canada’s involvement in the creation of the jet from its inception in the late 1990s, as well as the various parts made here — and all the people that employs as a result.

Rising U.S. trade tensions have some questioning if American-made fighter jets are still the right decision for Canada. For The National, CBC’s David Common looks at what goes into building the F-35 and finds a surprising Canadian contribution.

Given this history, and the current state of political affairs south of the border, Canada’s Industry Minister Melanie Joly told Radio-Canada she’s been pushing Lockheed Martin to provide more economic benefits to Canada if this country is to proceed with its purchase of the jets.

Each jet costs between $82 million and $100 million US ($115 million to $140 million Cdn). According to McIntosh, that figure contains about $3.2 million Cdn ($2.28 million US) worth of parts.

CBC News observed this integration of U.S.-Canadian parts and know-how first-hand during a rare visit to Air Force Plant 4, a government-owned facility operated by Lockheed Martin in Fort Worth, Texas.

Set in one of the largest American military aircraft plants, the production line spans more than a kilometre and a half. It takes about $1 million US ($1.4 million Cdn) a month just to keep it cool.

The highly precise and efficient manufacturing line has produced more than 1,200 fighter jets, which have been sold to 20 countries.

Due to security and proprietary concerns, CBC News was restricted in what could be filmed, but did get to see the massive assembly line from start to finish.

Canada’s contribution to the F-35 spans across the country. McIntosh noted, for example, that the horizontal tail for the F-35 is assembled in Winnipeg, while engine sensors come from Ottawa and composite materials that make up some of the panels are produced in Lunenburg, N.S.

According to Lockheed, 80 per cent of the jet is made somewhere else, before full assembly in Texas.

“The men and women that work here, along with all of our industry partners across the globe, are just very proud of what we do, helping defend freedom and all of our allied and partner nations,” said McIntosh.

100-plus companies in Canada have contributed to program

Each F-35 takes about 18 months to complete. At the beginning of the assembly line, each jet starts with just a wing. As it moves along each stage of the production process, it slowly starts to resemble an aircraft.

A Lockheed Martin test pilot who accompanied CBC on the tour was able to point out some of the Canadian parts on the jets themselves.

At each station, there’s a screen that indicates the country that has purchased that specific jet and what percentage of it is completed, along with other key information. CBC saw one of the 16 jets slated for Canada, which was in the beginning stages of assembly.

Canada is one of eight partner nations from the program’s inception, and a member of the joint executive steering board, meaning that Canada has had a seat at the table and has been involved in the decision process for major aspects of the program.

In a statement to CBC News, Lockheed Martin said, “The global F-35 program bolsters an allied defence industrial base, with projected economic benefits commensurate with a country’s program of record. The projected economic benefit of $15.5B CAD is commensurate with Canada’s program of record for 88 jets.”

Lockheed Martin says about 30 companies in Canada are currently involved in the F-35 program, employing about 2,000 Canadians. With a natural ebb and flow of contracts, the defence contractor says anywhere between 30 to 35 companies in Canada — though not necessarily Canadian-owned — participate in the program.

McIntosh says more than 110 companies in Canada have contributed to the program since its inception, and given that new contractors continue to be brought in, “there’s always going to be opportunities for more content on this airplane to be built in Canada.”

‘Proud to be part of the program’

The Canadian government has signed on to buy the F-35 A variant, but Canadian companies supply parts for all three of the jet’s variants.

For example, a company in Delta, B.C., makes a part of the foldable wing for jets that land on aircraft carriers that aren’t part of Canada’s military.

Another contribution comes from the picturesque town of Lunenburg, N.S., which houses a factory belonging to French aerospace and defence company Stelia. It’s just minutes away from Lunenburg’s colourful harbour, famously known as the home of the Bluenose, the racing schooner pictured on the Canadian dime.

Stelia makes panels from composites that are structural, lightweight and include stealth properties. The company supplies parts for all three varieties of the F-35.

“We’re full of very high-skilled, motivated … people with a lot of pride, and that kind of comes with being in a small town,” said Dave Mitchell, a senior program manager of defence at Stelia.

“All I can say is that we’re proud to be part of the [F-35] program … that’s going to be used by the Royal Canadian Air Force, NATO allies. It’s a good feeling to support the program.”

When asked how he would feel if Canada were to pull out of the purchase, Mitchell said that it would be “disappointing.”

“We’ve been a good, loyal supplier of very high-quality parts since basically the beginning of the program, and we want to continue to work on it, and we hope that that’s the direction we’re gonna go,” said Mitchell.

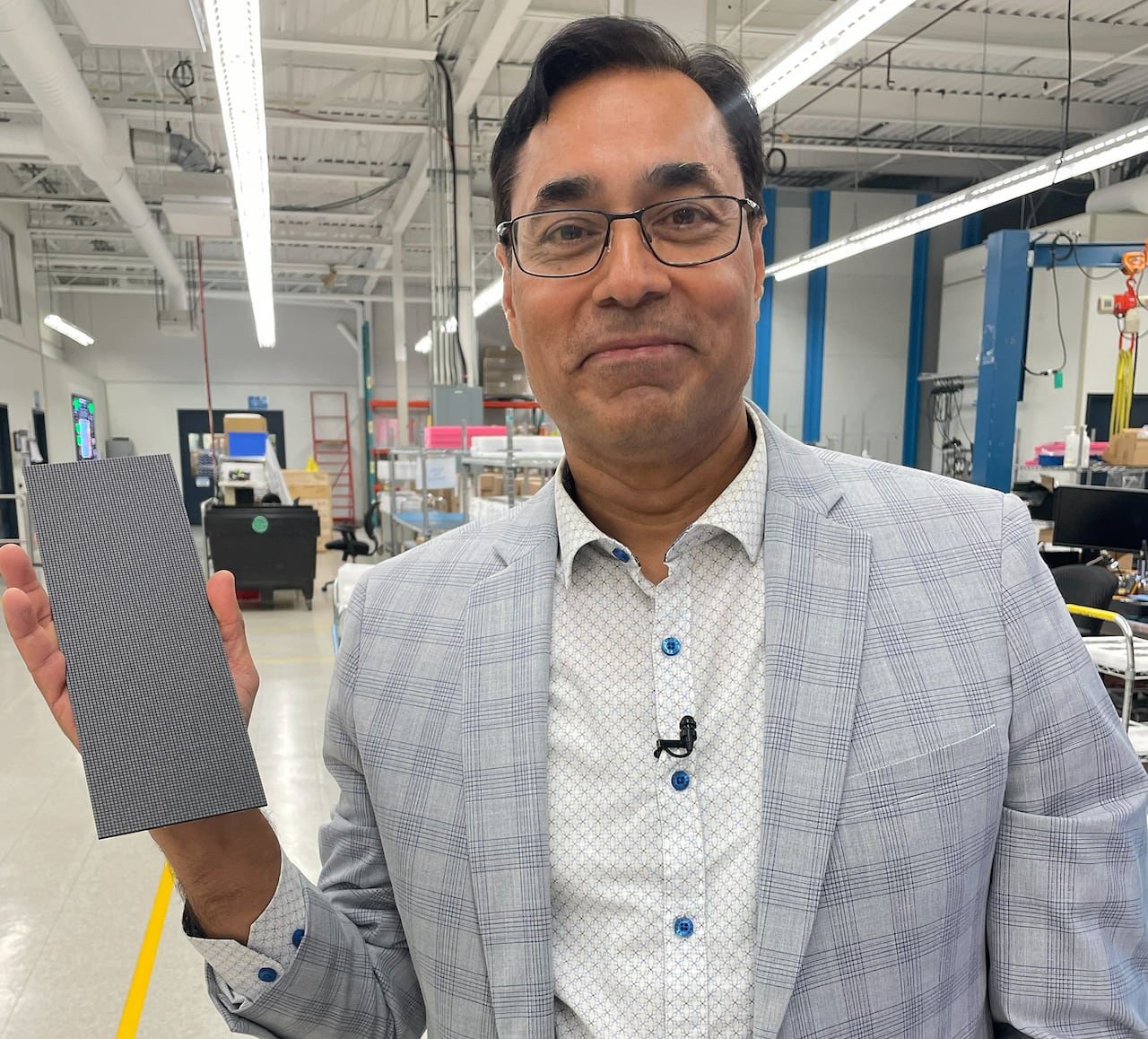

Also involved in the F-35 program is Christie Digital, a projector and LED display company located in Kitchener, Ont., a well-known hub for engineering and innovation. The company landed a contract with Lockheed Martin just last year to help build the next generation of F-35 flight simulators. Christie supplies the micro LED tiles for Lockheed Martin’s Amorphic Appearance Zero-Projector (AMAZE) visual display system.

It’s a 360-dome cockpit simulation that allows pilots to train in a safe, low-cost environment. According to Harminder Banwait, director of business development at Christie Digital, it will enhance night-training capabilities.

“I got a lot of pride in working with the team,” said Banwait. “It’s a lot of satisfaction for me personally, that I’ve had a long career so far, and to be able to deliver something that is unique and to be the first to market is really rewarding for me.”

Banwait says the contract with Lockheed Martin puts Christie’s LED product on the map.

‘Do we want to put all our eggs in one basket?’

While Canadian-based companies are reaping benefits from being involved in the F-35 program, not everyone is sold on the wisdom of the Canadian military purchasing these jets.

Alan Williams, a former assistant deputy minister at the Canadian Department of National Defence who once ran procurement, says the people doing the research have to provide the minister with the hard information regarding cost and operational capability from a “totally objective” standpoint.

Whether the F-35 is the best fighter jet is “a highly debatable point, because you’re talking not just about capability, but about cost as well,” said Williams.

“Do we want to put all our eggs in one basket? Important for the government to consider, and I’m sure that’s exactly what they’re gonna be looking at when they make this final decision.”

If Canada were to stick with purchasing just the 16 F-35s, it would need to look elsewhere to build its fleet. Some argue it should turn its attention to the Gripen jet, made by NATO ally Sweden, not only because of tensions between Canada and the United States in recent months, but because the Gripen is cheaper from an operational cost perspective.

“You have to remember that 70 per cent of the cost of an aircraft is its long-term support, not its acquisition,” said Williams. “And with regard to that, the Gripen E, for instance, is one-sixth the cost per hour flying as the F-35.”

The Gripen, which is produced by Saab, also appeals to the Canadian government because there’s the possibility it could be assembled in Canada.

The argument to stick with the F-35 is to avoid a mixed-fleet system, according to Williams. Whether or not Canada does end up getting all 88 jets, there will still be overlap with CF-18s that the Royal Canadian Air Force will eventually phase out.

“If I wanted to be truly objective, what we might lose in the F-35, we would more than gain in terms of industrial and technical events with whoever else we’ve gone with,” said Williams.

McIntosh at Lockheed Martin says that even if the Canadian military were to pull out of the purchase of the remaining 72 jets, Canadian-based companies can always continue to bid “at best value” for contracts in the F-35 program.

When asked if his company is fighting to maintain Canada’s business, McIntosh says, “We feel that we need to fight to keep every customer’s business.”